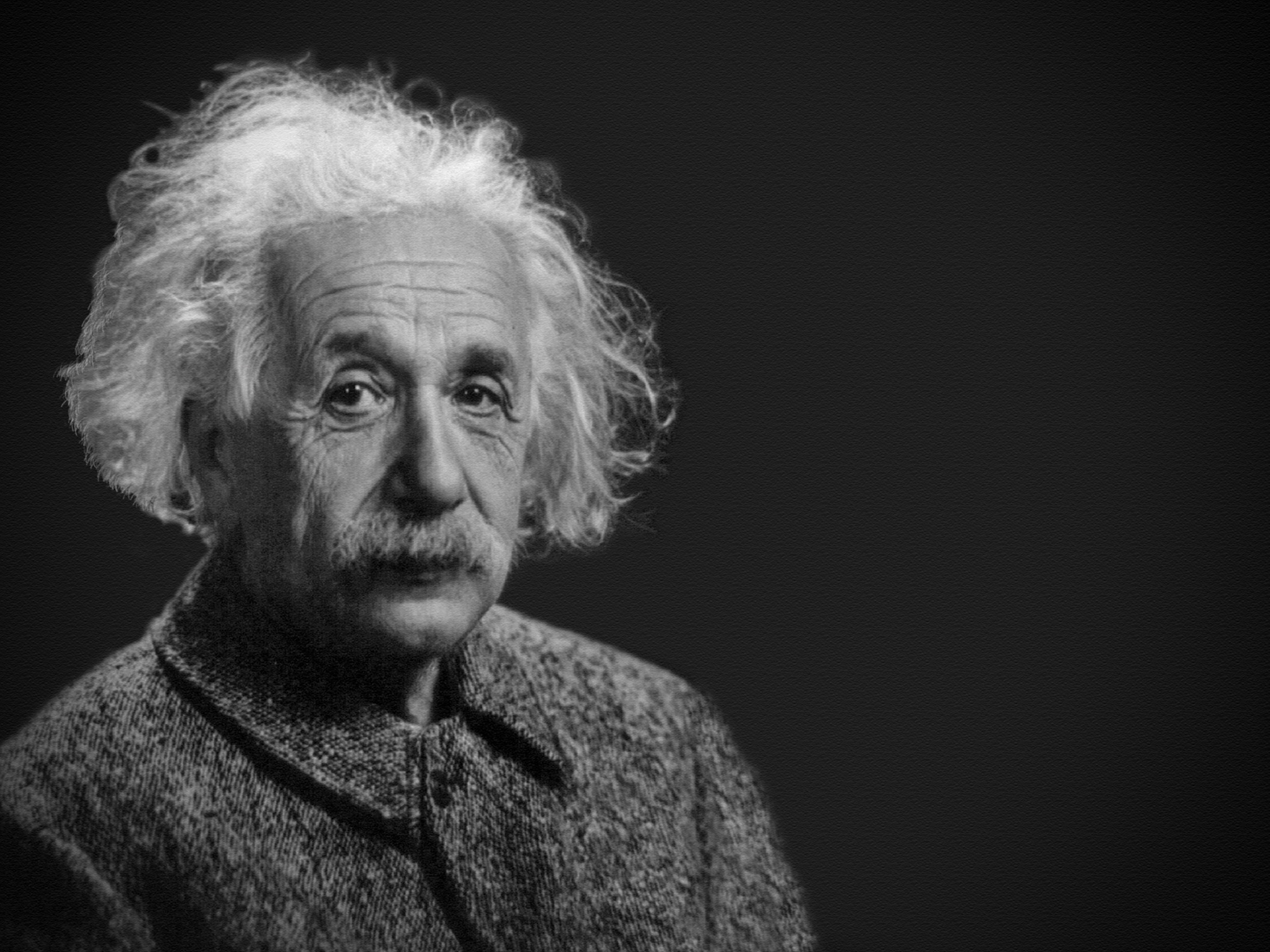

"Energy cannot be created or destroyed; it can only be changed from one form to another."

This much quoted line from one of the greatest minds the world has known (Albert Einstein) remains true, which is why the storage of energy, in a useful form, still remains the key.

For well over 150 years hydrocarbons have been the main energy carrier that the world has exploited, but now due to carbon emission concerns, we are looking to other energy vectors.

Energy storage comes in different forms with no single solution fitting all applications in terms of power density, discharge rate, life-time and efficiency. Rechargeable batteries (specifically Lithium Ion) are the front runner for a number of applications at present due to their ability to provide a good fit-for-purpose solution for many uses. Batteries are very good at variable discharge rates and efficiency and with the price of lithium-ion batteries declining sharply in recent years (having been developed and scaled for widespread use in phones, laptops, cars etc..), they certainly have a role to play in the world’s energy management solution.

Lithium Battery Rack

However, Lithium Ion (Li-Ion) batteries are not best placed for long-term or large quantity energy storage. HydroGenesis’ stationary storage solution requires the ability to power a house, factory or power-hungry data centre for many hours per day, for consecutive days, weeks or months. High cost and short life-cycle restricts the use of batteries in power storage systems; this is where the hydrogen and fuel cell double-act step in.

The operation principle of batteries is comparable to that of hydrogen and fuel cells, both technologies transform chemically stored energy into electrical energy. In a battery the chemical energy is stored internally, whereas in a fuel cell the chemical energy (hydrogen) is supplied externally and can be continuously replenished (in our solutions via an onsite electrolyser). A future article will delve deeper into how fuel cells work.

Return of energy

On average, 80% to 90% of the electricity used to charge the battery can be retrieved during the discharging process. For the combination of electrolyser and fuel cell, approximately 40 to 50% of the electricity used by the electrolyser for hydrogen production can be retrieved by the fuel cell as electricity (for comparison hydrocarbons are only 20-35% efficient when used in an engine). Batteries are clearly favourable from this perspective but as long as the hydrogen is generated from excess renewable energy then there is still a net energy benefit especially for long term, large quantity energy storage. From a purely financial perspective, as long as the hydrogen is created via an onsite electrolyser from excess solar or wind production then the round-trip efficiency is not an issue.

Other than electricity, fuel cells produce heat, which accounts for the majority of the electrical efficiency losses. If this heat is captured, stored and used, then the overall system efficiency increases and can reach levels equivalent to (or even better than) battery round trip efficiencies.

Green?

There are environmental concerns to consider for both battery and hydrogen technologies. Production of Li-Ion batteries is energy intensive with a high carbon footprint, and their disposal is an environmental concern. Lithium at scale is often associated with resource depletion, ecological toxicity, and human health impacts, similarly with another Li-ion battery component, cobalt. A grid-scale hydrogen fuel cell solution has a far smaller environmental footprint than a battery storage facility of comparable scale and hydrogen fuel cells require no toxic chemicals, often associated with the manufacture of Li-Ion batteries. However, the storage of gaseous hydrogen requires thick steel walled cylinders (if Type I) and the steel industry is the third biggest industrial producer of carbon dioxide, globally.

The steel used to fabricate a Type I compressed hydrogen storage cylinder is less energetically costly, per unit of stored energy, than the materials that store electric charge in a battery (electrode paste, electrolyte, and separator). With more research and manufacturing of Type IV cylinders (made from composite material such as carbon fibre with a polymer liner), which are used in fuel cell cars and mobile storage, the material cost and energy cost of this storage type will decrease in the future, improving the green credentials of the hydrogen fuel cell storage solution.

Time

Most large scale battery-based solutions store energy from one to four hours. Longer-lasting solutions (12+ hours) are typically not cost-effective. Batteries last for a finite number of recharge cycles, have long charging durations, self-discharge over time, have a limited lifespan and are difficult/impossible to economically recycle. When correctly stored, hydrogen will retain its energy indefinitely, not “leak” like batteries and can be used to store larger amounts of energy economically.

Batteries offer fast responsiveness and high charge/discharge capacities so are capable of providing and absorbing large power gradients. While batteries respond in milliseconds, fuel cells require multiple seconds up to minutes to react; this is why the decision can never (at present technological stage) be either hydrogen or battery, it has to be both.