A key aspect to a HydroGenesis system is the storage of the hydrogen we produce by electrolysis. This is not as simple as many would initially believe (including us) mainly due to the lightness of hydrogen and therefore the low energy density by volume of the gas. The storage of hydrogen has been performed for a long time but in relatively modest amounts – even though the global demand for hydrogen is over 70 million tonnes (as discussed in a previous article, The Uses of Hydrogen), most of this hydrogen is produced and used on site rather than stored. As such, large scale storage solutions, which are going to be needed, are not yet commonplace.

There are a number of options for storing hydrogen such as keeping it as a gas, storing it as a liquid or as a chemical compound. Each storage method has its pros and cons related to the amount of hydrogen that needs to be stored, safely. The storage solution needs to consider the energy (and therefore cost) required to move the hydrogen between generation, storage and retrieval ready for consumption.

When storing hydrogen as a gas, the main consideration is how to store enough by weight to make it worthwhile. Unless we have the opportunity to use geological storage, where large underground salt caverns can be filled with hydrogen, we store gaseous hydrogen by compression; requiring energy input and safety considerations. Compressed hydrogen storage can vary from relatively low levels, around 50 – 60 bar, all the way up to over 1,000 bar. The amount of space required compared to the amount of compression is not too far off being linear at these levels of pressure, so you can store around twice as much hydrogen in the same space when doubling the pressure.

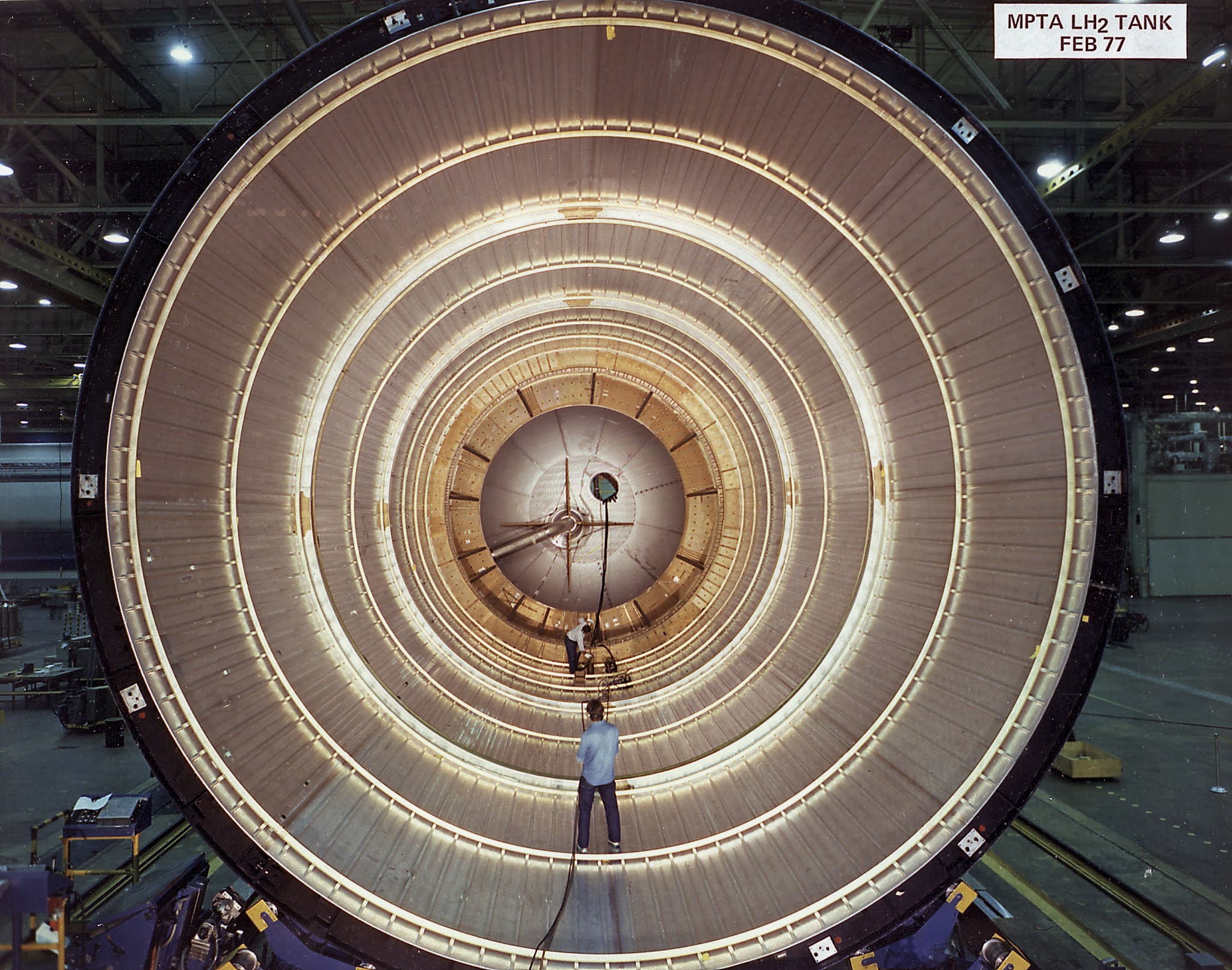

Another relatively established method of storage is to liquify hydrogen as is done for space rockets. The most difficult aspect of liquifying hydrogen is that it has an incredibly low boiling point at atmospheric pressure of -252.8 ˚C, so needs cooling to below this temperature, requiring lots of energy. It also needs keeping at this temperature so requires insulated tanks – the giant orange tank of the space shuttle was insulated to keep the liquid hydrogen from evaporating, as well as outside air from freezing on the surface of the container (inside of the tank shown below).

MPTA LH2 Tank, February 1977

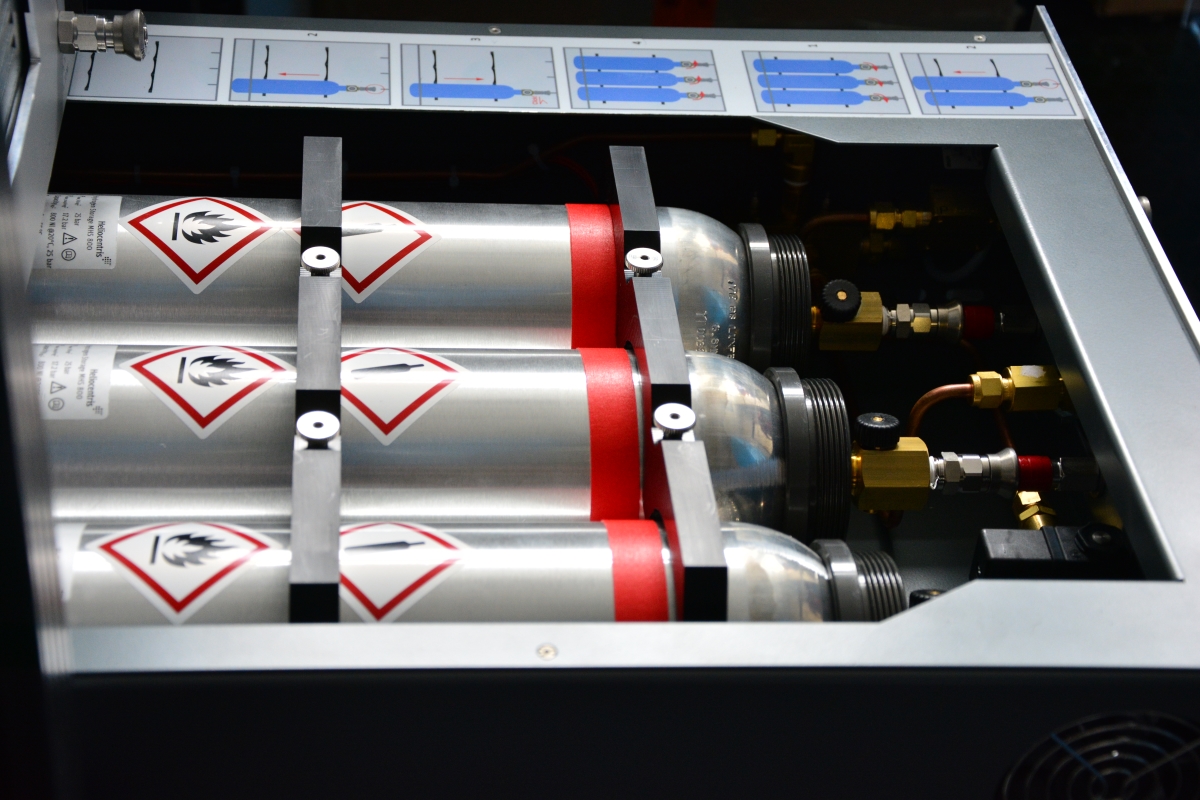

The third main method for hydrogen storage is to allow it to form chemical compounds. We discussed in the previous article What is hydrogen and why use it to store energy? that as an element hydrogen prefers to be bound to other elements at atmospheric conditions. We can use this characteristic and essentially introduce the hydrogen to solids or liquids that absorb or react with hydrogen to bind with it. The key to chemical storage is to create a compound that binds easily with lots of hydrogen molecules, but forms bonds that can be easily broken to free the hydrogen without inputting much energy. The compounds are ideally made from abundant ‘cheap’ materials, have a low environmental impact, form and dissolve at low temperatures; all leading to safe and economical storage. Current leading chemical storage options are solid metal hydrides (as seen in canister form in the image below) and liquid ammonia with research going into many other opportunities such as aqueous hydrogen peroxide.

Metal Hydride Storage Canisters

At HydroGenesis we are initially planning to store hydrogen as a compressed gas as we feel the existing technology allows us to do this safely and on the scales we require. Even choosing to compress hydrogen gives us a lot of options in terms of pressure and cylinder type…

There are four types of pressurized cylinders that exist on the hydrogen storage market, each with their specific characteristics –

Type I cylinders are the most simplistic, they are seamless all metal cylinders. Type I cylinders are typically made from stainless steel and have thick walls to cope with high pressures; as such they weigh a large amount so most suited to stationary applications and can be relatively expensive due to the amount of metal required. All of the metal cylinders need to be carefully designed to account for hydrogen embrittlement, which can cause the cylinders to fail in a relatively short amount of time.

Type II cylinders are also metal cylinders but are supported along the length of the tube by carbon fibre with resin wrap. This allows the cylinder to be made with slightly less metal as the walls do not require quite as much metal. Type II vessels are typically used for high pressure stationary storage applications as they are strong but their weight is still high.

Type III cylinders are similar to Type II in that they are metal tanks supported by carbon fibre and resin wrap but all over the cylinder including the dome ends not just the middle tube section. Due to this extra support, type III vessels are much lighter than types I and II so are applicable for portable applications.

Type IV cylinders are completely non-metal and consist of a polymer lining supported by a complete carbon fibre resin wrap. Type IV cylinders are being used primarily for transport applications as they are significantly lighter than any of the cylinders made from metal, meaning the vehicle’s range is not adversely affected by the weight of the tanks. The picture below shows type IV cylinders developed for the Toyota Mirai hydrogen car. They are lightweight, can hold hydrogen at pressures of 700 bar and are designed to withstand large impacts from crashes as well as fires but are typically expensive and have shorter life cycles.

Hydrogen tanks for Toyota Mirai

At HydroGenesis, we are looking forward to new hydrogen storage solutions coming onto the market as the hydrogen economy advances. We feel that advancements in hydrogen storage will be a major contributor to normalizing hydrogen use as an energy vector and making it an economical option for mass adoption.